Description

Essential details

Applicable Industries:

Building Material Shops, Manufacturing Plant, Construction works

Showroom Location:

Bangladesh

Condition:

New

Type:

Paving Block Making Machine

Brick Raw Material:

CONCRETE

Processing:

Brick Production Line

Method:

Hydraulic pressure

Automatic:

Yes

Production Capacity (Pieces/8 hours):

4000-60000 Pieces/day

Place of Origin:

Shandong, China

Brand Name:

Hongfa

Voltage:

220V/380V/440V or as your request

Dimension(L*W*H):

8400*1700*2950mm

Warranty:

1 Year

Key Selling Points:

High-accuracy

Brick size:

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 400*200*200 mm, 230*220*115 mm

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Marketing Type:

Ordinary Product

Warranty of core components:

1 Year

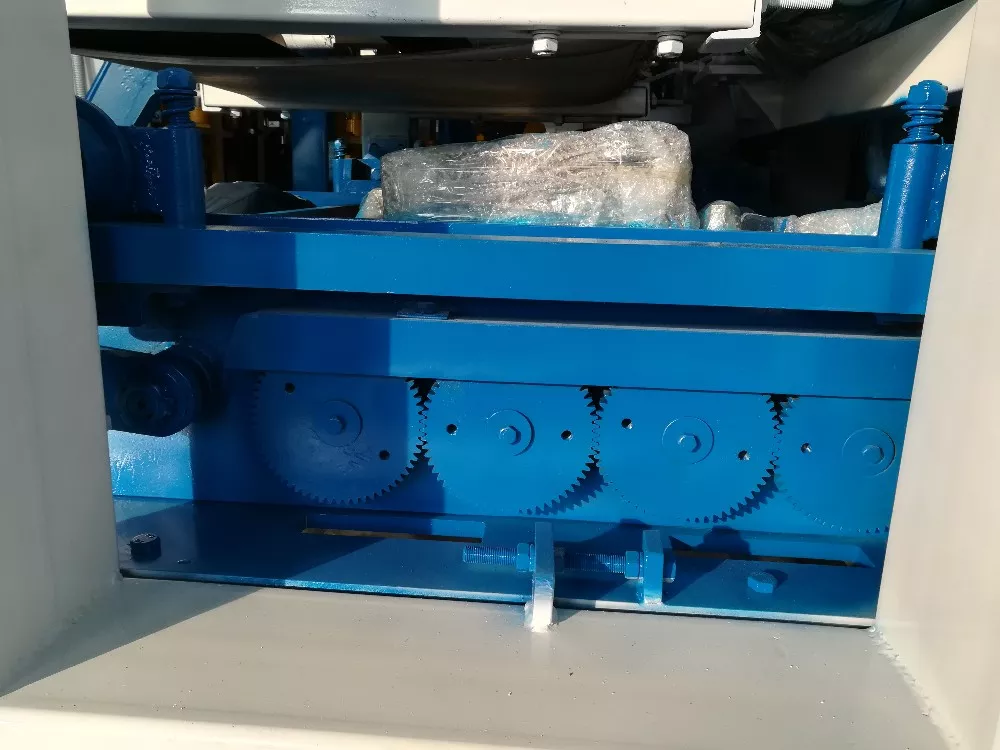

Core Components:

PLC, Pressure vessel, Pump, Gearbox

After-sales Service Provided:

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

Raw material:

concrete

After Warranty Service:

Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

Bangladesh

Certification:ISO9001

QT 8-15 manual interlocking block machine,block machine

priceShandong Hongfa QT 8-15 brick block making machine,styrofoam block machine

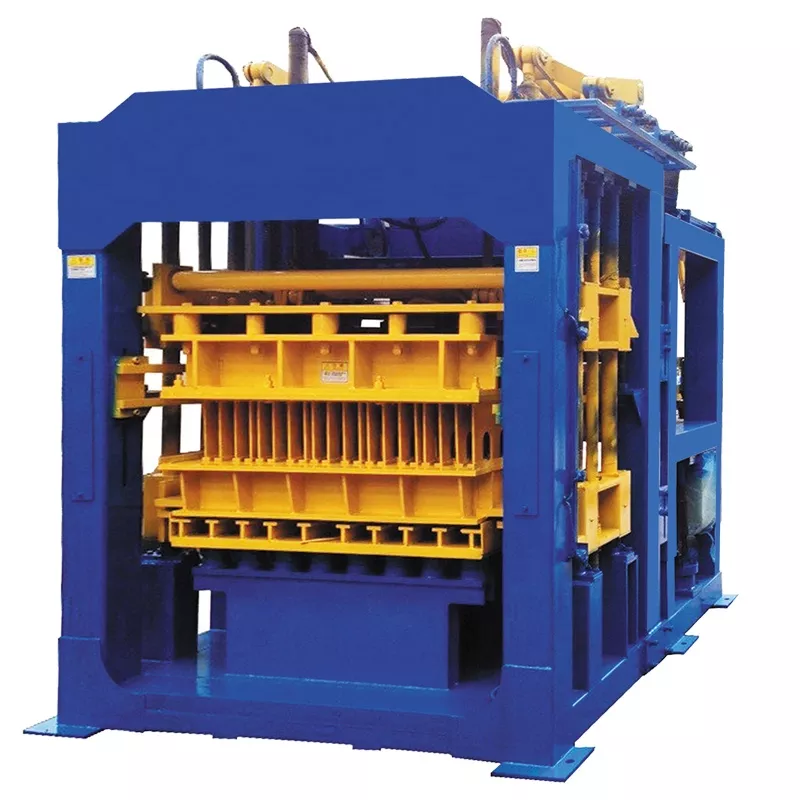

QT8-15B Concrete Block, Paver & Curbstone Production Line

ⅠBrief introduction

1.The machine can serve several purposes and can produce pavement bricks, riverside bricks, revetment bricks ,square bricks

,grassed bricks and so on with different moulds.

2.Low frequency in feeding material, high frequency vibration. Platform vibrating works together with mould, So that the concrete

can be fully fluidified and exhausted in two or three seconds to reach the high density.

3.The advanced technique of hydraulic-controlled proportion can handle the oil press and amount of the system freely,therefore

,different materials can be able to produce the high quality products.

4.All the procedures are operated by PLC and equipment with out and in date device to realize person-machine conversation. Control

system also including the advanced safe logical system and fault diagnosis system.

ⅡControl system:

PLC intelligent control. Man-machine interface, control system equipped with complete logic control, production program,

malfunction diagnosis system and remote control function. So it doesn’t need a professional person but only need a simple trained

one to the operator.

Product scope: It produces various bricks/blocks including color-face bricks (layered material feeding),through-body tiles,lock

linkage blocks, road curb bricks, hydraulic blocks,hollow blocks, perforated bricks, and standard bricks etc.

Ⅲ Main Technical Specifications

Overall Dimension 8400×1700×2950(mm)

Rated pressure 21MPa

Main vibration form Platform vibration

Acceleration of vibration 15-20g

Exciting force 695kn

Cycle Time 15-25 seconds

Vibrating Frequency 2800-4500 rolls/minute

Overall weight 9000kg

Motors Power 37KW

Pallet Size 950*900(mm)

Raw Materials crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, expanded perlite, and other

industrial wastes

Applied Products concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and

landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc.

4 Productivity of QT8-15 block making machine

| Samples | Size mm | Cycle molding |

QTY /Mould |

Per hour |

| Hollow brick | 400*200*200 | 15–25S | 8 | 1650~1800pcs |

| 400*150*200 | 16–20S | 10 | 1800-2250pcs | |

| Prorous brick | 240*115*90 | 15–25s | 21 | 4200~5000pcs |

| Solid block | 240*115*53 | 15-17s | 42 | 9000-10000pcs |

| Color brick | 225*112.5*60 | 25~30s | 21 | 2520~3020pcs |

Reviews

There are no reviews yet.